5HHS-22M型低温谷物干燥机

5HHS-22M Type V low temperature grain dryer

混流式干燥,高效率烘干技术:

5HHS-22M型干燥机的干燥箱采用角管交叉导流,3M*2.46M*2.4M大型干燥箱加风箱结构采用负压低温干燥技术,多级混流烘干与缓速相结合的烘干工艺,相比传统烘干机烘干效率大幅提升;独特的角管混流式烘干技术保证烘干谷物在烘干时全方位无死角和谷物烘干后的水分均匀性。

智能自动化控制,低温烘干,实时持续监控:

5HHS-22M型干燥机采用低温烘干,机器上的温控系统可控制烘干温度,用户可根据谷物品种不同自行随意调节,设备控制系统采用PLC系统自动控制实时监控烘干温度,风温、粮温实时监测和控制,谷物烘干自动化全程无忧;在线水分仪实时监测谷物含水量,烘干谷物达到用户设定的水分值后自动停机,防止过度烘干。

独特的一机多用排粮机构,烘干品种多、效率高:

该机具有多功能设计,可干燥水稻、油菜籽、小麦、玉米等颗粒状谷物。干燥层采用混流风道,谷物干燥效率高。谷物从谷底输送到谷仓的过程将使干燥的谷物自然冷却。机器顶部设有谷物撒粮装置,保证谷物能顺畅地卸入仓内,并保证谷物在仓内撒粮更均匀,干燥后谷物水分均匀。在线水分传感器实时监测谷物的水分含量,并在谷物干燥达到用户之前设定的水分值后自动停止。

互联网+工业4.0智能控制系统:

设备电箱带有工业4.0智能控制系统(选配),该系统只要在有英特网的地方用户就能随时全面监控设备状态,用户使用智能手机就能轻松掌握设备运行状况;互联网+时代的新型售后服务模式,问题精准定位,售后智能响应,给您提供快速,高效,精准的售后服务。

Mixed-flow drying, high efficiency drying technology:

The drying chamber of the model 5HHS-22M dryer has angle-pipes with cross-diversion structure. the drying cabinet, overall size 3M*2.46M*2.4M, adopts negative pressure low-temperature drying technology. The drying process improved by multi-stage mixed-flow drying technology is much more efficient than traditional dryer. The unique corner tube mixed-flow drying technology ensures quality of drying grain. There is no dead angle in all directions and moisture uniformity of grain after drying.

Intelligent control, low temperature drying, real-time monitoring mechanism:

The model 5HHS-22M dryer adopts low temperature drying technology. The temperature control system on the machine can control the drying temperature. Users can adjust the drying temperature.freely according to the variety of cereals. The equipment control system adopts PLC system to automatically control the drying temperature in real time. There are many sensors in the controlling cabinet, including the air temperature and grain temperature sensor, which ensure the whole drying process are tree from worry. The moisture senser continuously and automatically monitor the moisture content of grain in real time, stops automatically after drying the grain reaches the moisture value previously set by the user, it also can prevent drying grain from the excessive drying.

Unique one-machine multi-purpose grain discharging mechanism:

This machine has multi-function design, can dry rice, rapeseed, wheat, corn and other granular grains. The drying layer adopts mixed flow air duct, and the grain drying efficiency is high. The process of transporting grain from the valley floor to the barn will allow the dry grain to cool naturally. The top of the machine is equipped with grain sprinkling device to ensure that the grain can be unloaded smoothly into the warehouse, and ensure that the grain is evenly distributed in the warehouse, and the grain moisture is even after drying. The online moisture sensor monitors the moisture content of the grain in real time and automatically stops when the grain has dried to a preset moisture value set by the user.

Exclusive Internet+Industry 4.0 Intelligent Control System:

The equipment cabinet has an exclusive industrial 4.0 version intelligent control system, which can enable users to monitor the state of the equipment by a cell phone at any time as long as there are any place where can receive the Internet signal. Users can easily know the running status of the dryer by using the APP downloaded on smart phones, computers or iPads. The new after-sales service model with the Internet can position the fault precisely. Moreover, the intelligent response system in new area can provide you with rapid, efficient and accurate after-sales service.

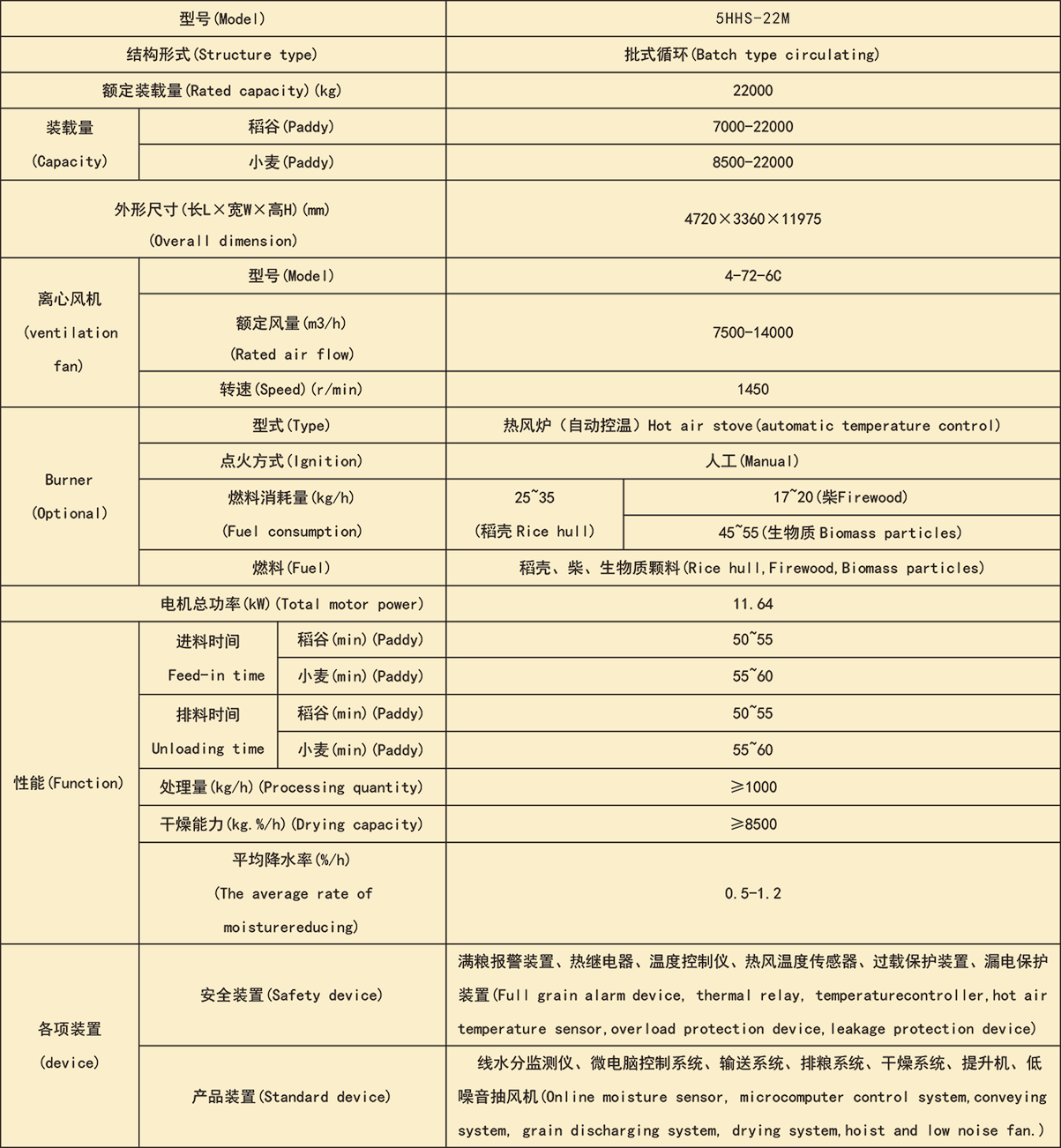

5HHS-22M型低温谷物干燥机——技术参数

备注:

1、本表所列之性能及降水率为参考数值,稻谷水份是由28%烘至15%;小麦是由30%烘至14%为止的数值,实际数值会因外气温度、相对湿度、干燥品种、热风温度、进风温度、热源类型和品质及干前、干后含水率而有所差异。

2、上表中的数据仅供参考,因产品技术不断改进,本公司更改后恕不另行通知。

1、 he performance and precipitation rate listed in this table are reference values, the water content of rice is reduced from 28%. to 15%, and the value of wheatis from 30%to 14%. The actual value vary according to external gas temperature, relative humility. dry variety, hot air temperature, inlettemperature, type and quality of heat source, and moisture content before and aterdy.

2、Specification is subject to change without prior notice.

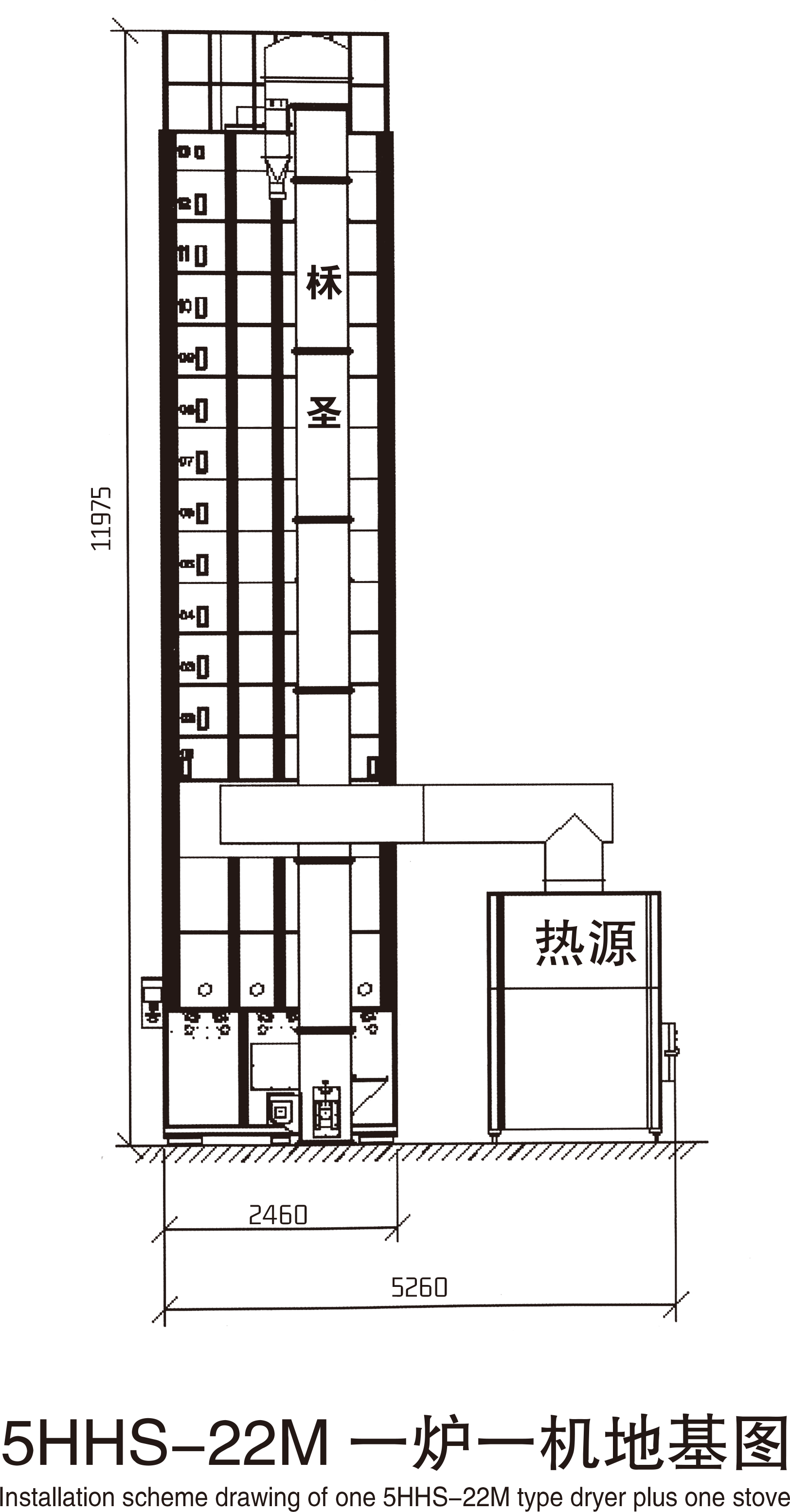

5HHS-22M型低温谷物干燥机——标准配置地基图

单位 (mm) Unit (mm)

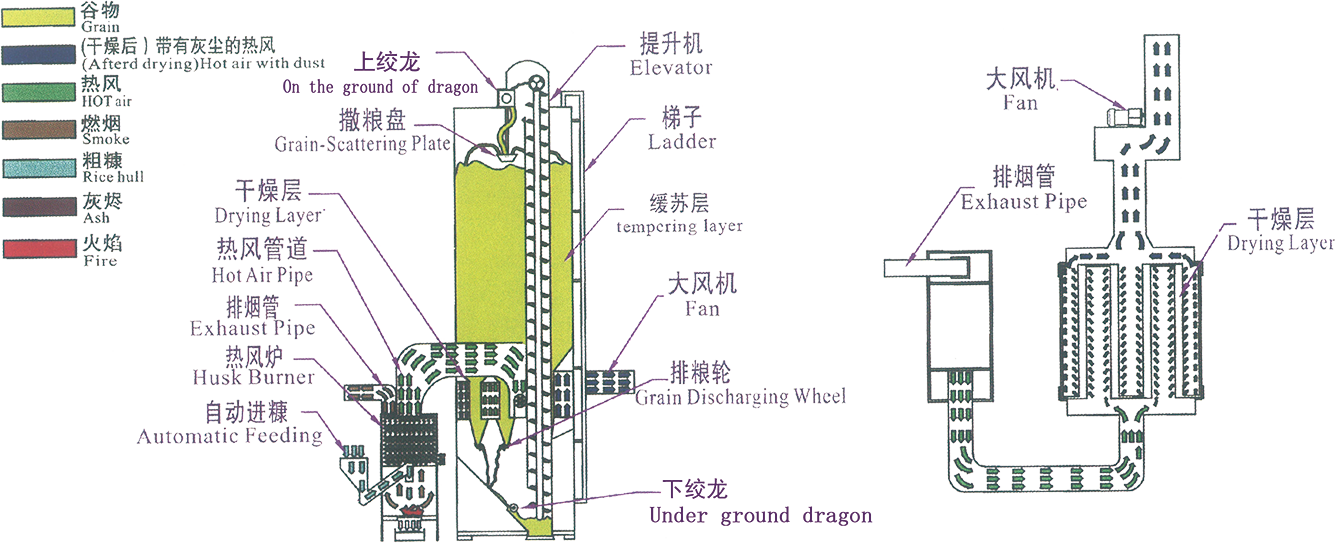

5HHS-22M型低温谷物干燥机——原理图

The schematic diagram of 5HHS-30Mtype grain dryer

工作原理

单个批次谷物进入干燥机后,通过电器件的相互配合运行使得谷物在干燥机中进行有序循环,再由热风炉燃烧燃料产生热风,在单台电动风机的作用下,让热风通过混流式干燥层的风道,穿透和加热谷物,通过空气流动带走谷物中的水分,带有水分的废气经过风机的吸力通过管道排出机外,干燥的谷物经过自动在线水分仪检测达到预先设置的水分点后、停机、干燥完成。

Working principle

After a single batch of grain into the drying machine, use the electric parts together running makes grain an orderly circulation in the dryer, again by hot blast stove burning fuel to produce hot air, under the action of a single electric fan, let air by mixed flow drying layer of air duct, penetrate and heating grains, take away moisture from the grain through air flow, The exhaust gas with moisture is discharged from the machine through the suction of the fan through the pipe, and the dry grain is detected by the automatic online moisture meter to reach the preset moisture point, then the machine is stopped and the drying is completed.

上一篇:5HHS-32M型低温谷物干燥机

下一篇:5L系列节能环保生物颗粒热风炉